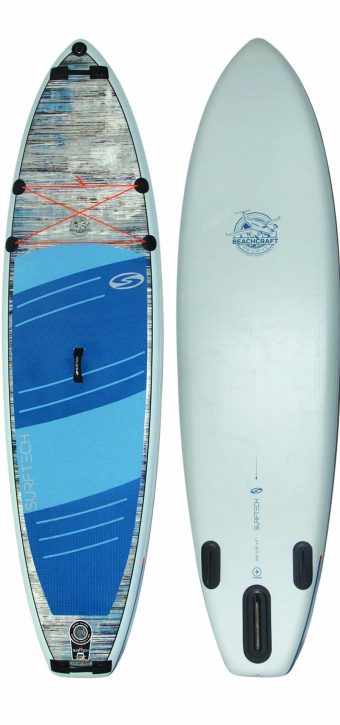

The Surftech Gulfstream (Air-Travel) package is made from Air-Travel technology and is the whole package! The Surftech Gulfstream is available in one size: 10’2″.

Dimensions

10’2″ – Width 32″, Thickness 6″, Volume 304L

The Package

The Surftech Gulfstream (Air-Travel) comes as a package including: board, paddle, 9″ fin with key-less screw, repair kit, valve tool and roller backpack with dual-action air pump.

Technology

Air-Travel

The Air Travel Inflatables are made of high-quality puncture-resistance PVC Drop-stitch material to create a strong, rigid SUP that can go anywhere and stores easily. The double sidewall and dual-layer deck/bottom make Surftech Inflatables the most durable construction on the market. Surftech Inflatables come with dual-action hand pump to transform from duffel bag sized to a full-sized SUP. 15-18psi.

Additional Features

- Deck tie-downs

- Padded handle

- Drop-stitch material

- Roller bag, 3-piece paddle, pump, fin + repair kit